Producing Emission Free Natural Gas

Our group offers an integrated one-stop-shop solution to gas companies that can access the deep-sea gas hydrate fields to produce emission free Natural gas with integrated CCS (Carbon Capture & Sequestration process)

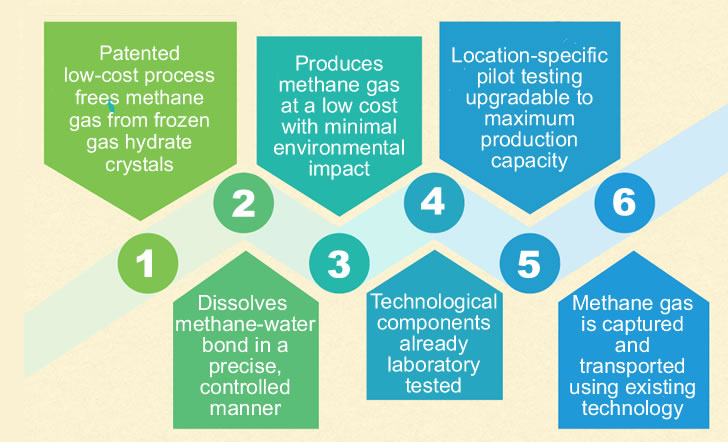

By using our patented REHM technology to control and customize the electromagnetic energy spectra usage, it is possible to:

- Dissociate the gas hydrate economically into methane and water

- Maximize propagation within a specific reservoir

- Minimize energy usage

- Maximize energy transfer efficiency.

Comprehensive computer simulations, based on a location-specific model, optimizes the energy usage for specific gas hydrate reservoir characteristics and properties.

All REHM-related system components needed by gas companies to produce methane from deep-sea gas hydrates are provided by our commercial, industrial, and academic partner organizations.

They cover everything from location-specific data collection and validation, to engineering, construction, and operation in deep water.

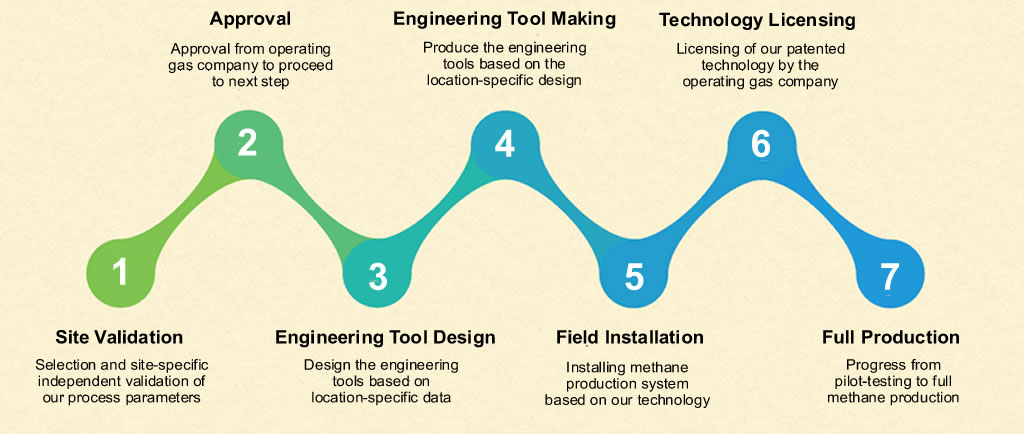

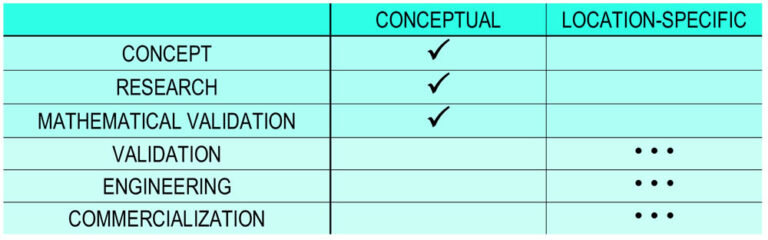

A 7-step implementation model provides a clear operational interface between the operating gas company and our commercial, industrial, and academic partner organizations

- The first step is the selection of the most promising gas hydrate location for methane extraction. This will be based on earlier drilling and coring, and guided by market demand for the locally produced methane, and available onshore and offshore resources and infrastructure. Site selection would be followed by location-specific, REHM-related data collection and validation by an independent academic institution and/or commercial laboratory.

- The location-specific empirical data thus generated helps the gas company evaluate the suitability of the selected location and give approval with the necessary funding to proceed to the next step.

- The location-specific data will then be used to design the engineering tools needed for the implementation of the REHM technology component, together with a cost estimate for their production.

- The location-specific engineering tools needed for the REHM system will then be produced, based on their design.

- These engineering tools needed by our REHM process for pilot testing will then be integrated into a standard gas-extraction installation owned by the operating gas company.

- Once the pilot testing phase starts producing methane, an agreed licensing fee for our patented REHM technology, payable by the operating gas company, will be based on fiscal metering at the gas production facility.

- Progress from the pilot testing phase to full-scale production of methane from the selected gas hydrate field.

This prudent approach will clear location-specific technical and operational uncertainties early, before investing in designing, making, and installing the location-specific, REHM-related engineering tools for pilot testing.

The estimated initial cost of production of methane from gas hydrates, using a tie-back to an existing deep-sea gas facility, will be about 60% of the infrastructural and distribution costs of re-gassed LNG. However, as experienced in other parts of the world, this cost will decrease as the gas hydrate industry using our technology matures.

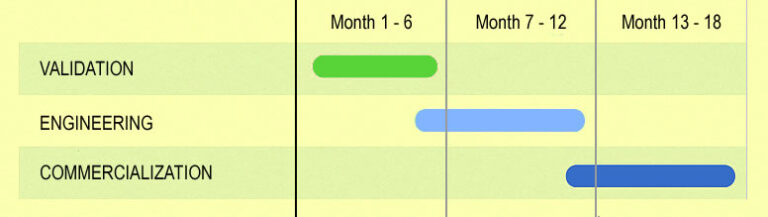

The project timeline for pilot testing for methane production will typically be 18 months:

Location-specific validation: month 1 – 6;

Engineering: month 6 – 12; Commercialization: month 12 – 18,

with some overlap.